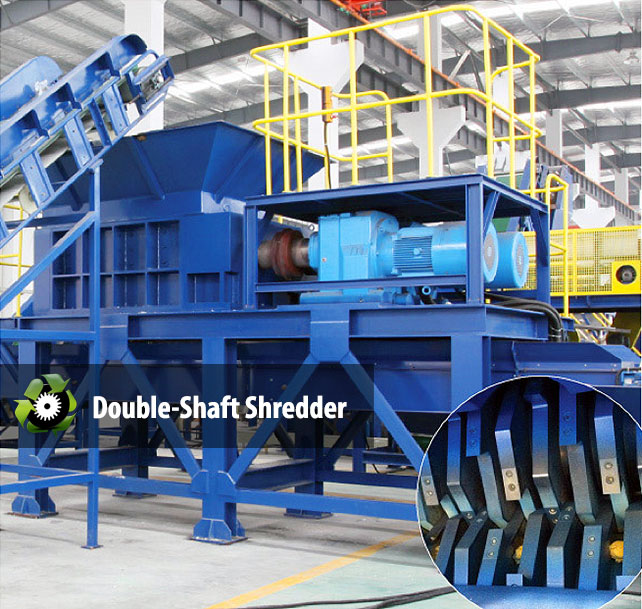

Product Description

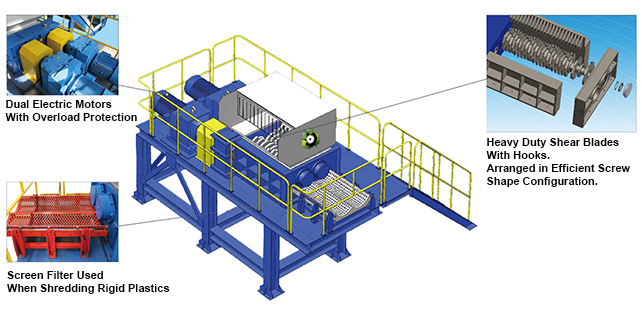

Our heavy-duty double-shaft shredders are a perfect addition to our standard PP / PE film washing line especially for washing plants requiring larger capacities. This low-speed, high-torque machine is used primarily to “pre-cut” entire bales of PP/PE film at volume speeds.

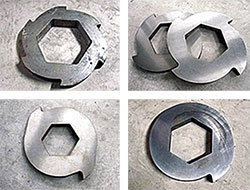

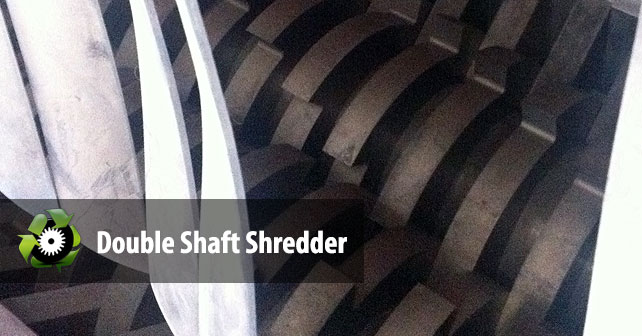

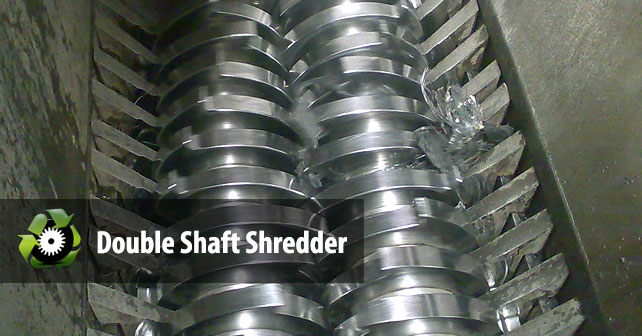

At the core of the double-shaft shredder are shear blades mounted on 2 hexagonal shafts that rotate into each other producing a cutting / shredding motion. These hooked styled shear blades allowing the shredder to quietly shred high volumes of PP / PE film into random, smaller pieces between 1-5 inches. The low speed of the rotors also ensures that little or not dust is generated.

At the core of the double-shaft shredder are shear blades mounted on 2 hexagonal shafts that rotate into each other producing a cutting / shredding motion. These hooked styled shear blades allowing the shredder to quietly shred high volumes of PP / PE film into random, smaller pieces between 1-5 inches. The low speed of the rotors also ensures that little or not dust is generated.

As our double-shaft shredders are usually placed in front of the most demanding jobs, the frame and structure of our shredders use high-thickness sheets and tubular. The shear blades are treatment strengthened and use only the highest quality SKD11 steel (D2 equivalent) to ensure against dulling. Depending the capacity you require, we offer a variety of standard double-shaft shredders for your choosing.

Specifications

| Model # | Main Motor Power | Number of Blades | Rotating Speed (rotations per minute) |

Approx. Capacity |

| SSJ400-800 | 2 x 22KW | 16 / 26 | 25 / 35 RPM | 1,500 KG/H |

| SSJ400-1200 | 2 x 30KW | 24 / 40 | 25 / 35 RPM | 2,500 KG/H |

| SSJ450-800 | 2 x 30KW | 16 / 26 | 18 / 28 RPM | 3,000 KG/H |

| SSJ450-1200 | 2 x 45KW | 24 / 40 | 18 / 28 RPM | 4,000 KG/H |

More Images

Ordering

Our lead time for single pieces of equipment is 30 days from the signing of purchase contract. For custom orders such as complete washing lines, the lead time is between 60 – 90 days. Actual lead times will depend on the project’s complexity as well as our factory’s availability.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.