Product Description

A float sink separation tank separates materials that sink from these that float. In PP / PE film recycling, this is an essential piece of equipment that removes a majority of contaminants such as sand, rocks, glass, metals, other plastics, and more.

The theory behind the float sink separation tank is quite simple, the density of water, which is 1g/cm3, is used to separate materials. For all materials entering the separation tank, anything with greater density will sink, while materials with lower density will float. For the purpose of our PE film washing line, PP / PE film (for those that are wondering, PP and PE have densities around .93g/cm3) will float while contaminants will sink.

The theory behind the float sink separation tank is quite simple, the density of water, which is 1g/cm3, is used to separate materials. For all materials entering the separation tank, anything with greater density will sink, while materials with lower density will float. For the purpose of our PE film washing line, PP / PE film (for those that are wondering, PP and PE have densities around .93g/cm3) will float while contaminants will sink.

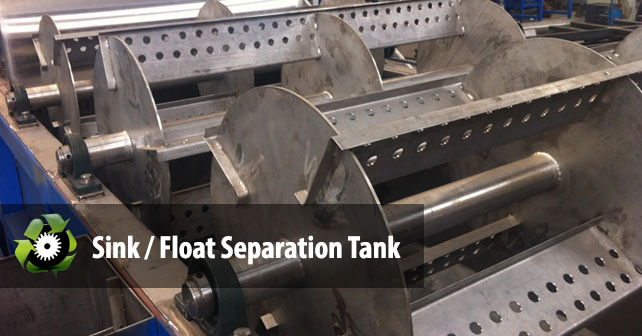

The contaminants that sink, a slurry mix of various materials, are removed from the float/sink separation tank via screw conveyors and collected for disposal. Large rotating paddles move the floating PP / PE film forward onto the next piece of equipment.

Ideally, we want the PP / PE film to soak in the water for longer periods of time. This not only allows for more cleaning of the material, it will also ensure enough time is given all sinking contaminants to make its way to the bottom of the tank. Hence, we offer a standard 4 meter separation tank with the option of extending it to 6 meters.

To ensure the durability of the water separation tank, the interior as well as rotating paddles on top are made with type 304 stainless steel that is strongly resistant to both oxidation (rust) and corrosion.

Specifications

| Interior Width: | 1500mm – 2000mm |

| Total Length: | 4 – 6 meters |

| Interior Material: | Type 304 Stainless Steel |

| Exterior Frame: | Carbon Steel |

| Screw Conveyor Motors: | 5.5KW + 3.7KW |

| Rotating Drum Motors: | .37KW + 2.2KW |

More Images

Ordering

Our lead time for single pieces of equipment is 30 days from the signing of purchase contract. For custom orders such as complete washing lines, the lead time is between 60 – 90 days. Actual lead times will depend on the project’s complexity as well as our factory’s availability.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.